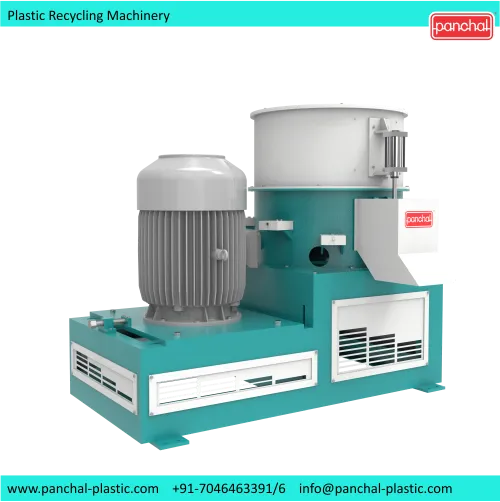

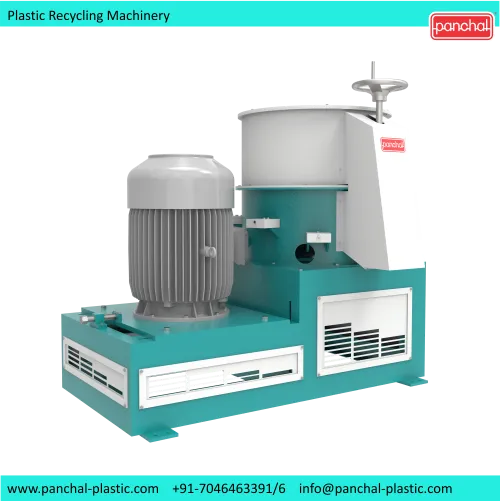

Modern plastic recycling requires precise agglomeration technology to handle diverse materials efficiently. Our systems are engineered for maximum throughput with minimal energy consumption.

Key features of our agglomeration process:

- High-torque cutting mechanisms for consistent particle size

- Precision temperature control zones

- Automated feed rate adjustment

- Energy recovery systems

OPTIMIZING RECYCLING OPERATIONS

To achieve peak performance with your agglomeration system:

- Implement pre-sorting for material consistency

- Maintain regular blade inspections

- Monitor temperature profiles

- Schedule preventive maintenance

The Simple Solution to Plastic Pollution: How Agglomerators Make Recycling Easy

Plastic pollution is probably the largest environmental issue we are dealing with today. Tons of plastic waste are dumped into landfills, oceans, and even our food chain every year. Recycling would be the solution, but some plastics—snack packaging, shopping bags, and thin films, for instance—are too intricate to recycle using conventional methods.

That's where agglomerators come in. These machines offer a smarter, more efficient way to recycle plastic waste that would otherwise be thrown away. In this article, we'll explain what agglomerators are, how they work, and why they could be a game-changer in the fight against plastic pollution.

What Is an Agglomerator?

An agglomerator is a recycling machine that converts plastic trash into solid, dense pellets. While typical shredders merely cut plastic into fragments, agglomerators heat and friction plastic waste so that it is melted and reshaped into something that can be reused by factories.

Here's the analogy:

- Shredders = Scissors (cut plastic into small pieces).

- Agglomerators = Blender + Oven (melt and reshape plastic into something new).

This is an excellent process for thin, light plastics that are too small for most recycling facilities to process.

How Does an Agglomerator Work?

The process is effective but straightforward:

- Shredding – Plastic waste (such as bags, wrappers, or packaging) is initially cut into very small flakes.

- Mixing & Heating – Flakes are fed into a revolving chamber equipped with spinning blades that produce fast friction to melt the plastic rather than burning it. Other equipment introduces a certain amount of water to regulate temperature.

- Pelletizing – Plastic melted together when solidifying and becomes small, uniform pellets. The pellets are sold to manufacturers to produce new goods.

The whole process is faster and more energy-efficient than traditional recycling methods.

Why Do Agglomerators Exist?

- They Process "Problem Plastics"

A majority of recycling plants are unable to process thin plastics like:- Store bags

- Bubble wrap

- Wrappers (candy wrappers, chip bags)

- Stretch wrap (used for packaging)

- They Save Money

Plastic waste-producing businesses (farmers, farms, shops, factories) have to pay to get rid of it. Using an agglomerator, they can recycle the waste into usable pellets—to sell or use to make their own products. - They're Space-Saving & Efficient

Unlike huge industrial recycling plants, agglomerators are compact in size, and hence suitable for:- Small recycling companies

- Small communities

- Factories who wish to recycle waste on their own

- They are Good for the Environment

Each ton of plastic recycled translates into:- Less oil being utilized to produce new plastic

- Less plastics contaminating nature

- Less carbon emissions resulting from plastic production

Who Uses Agglomerators?

Farmers

Plastic agriculture—such as silage wrapping, greenhouse film, and irrigation tubing—usually ends up in the landfill or incinerator. Farmers are able to recycle the waste as pellets to create fence posts, plant pots, or farm plastics anew using agglomerators.

Factories & Manufacturers

Factories create a majority of plastic waste when they produce. Rather than discard them, they can use an agglomerator to transform waste into reusable material.

Recycling Plants

Thin plastics are a challenge for some recycling facilities. Agglomerators assist them in recycling more materials, raising recycling levels.

Small Businesses & Startups

Elsewhere, businessmen gather plastic rubbish from markets and roads and afterwards sell them in pellet form by using small agglomerators. It generates employment and also purifies the environment.

Success Stories in the Real World

Brazil: Plastic Bags to Furniture

Plastic bags and films that would have otherwise become litter are collected by a Brazil recycling cooperative. Using an agglomerator, they recycle trash into pellets, which they employ to manufacture outdoors furniture, wastebaskets, and building material.

India: Street Waste → Pipes & Buckets

In India, mini recycling units utilize agglomerators to recycle plastic packagewaste. The pellets are sold to pipe, bucket, and other household item manufacturing plants.

USA: Retailers Recycling Their Own Plastic

A few retailers in the US now recycle plastic shopping bags and packaging via mini agglomerators within the supermarket itself, reducing waste and transport expenses.

Can Small Communities Afford Agglomerators?

Industrial agglomerators are very costly, but smaller, cheaper models exist. Choices include:

- Shared Machines – A group or groups of companies can share their funds to purchase one.

- Mobile Units – Others come to villages or markets with agglomerators and process the waste there.

- Government & NGO Support – Schemes and grants assist recycling companies in acquiring the machinery they require to begin operations.

What Can You Do?

Even without an agglomerator, you can help:

- Sort Your Plastics – Find out if your community recycling center can take thin plastics (e.g., films and bags). If not, check for special collection sites.

- Buy Recycled – Purchase products that use recycled plastic to help drive demand for improved recycling.

- Educate – Spread facts on agglomerators and improved recycling practices.

The Future of Plastic Recycling

Agglomerators in themselves won't cure plastic pollution, but they're a step in the right direction. By reducing the cost of recycling "problem plastics," they close the loop—turning garbage into something worth selling, not rubbish.

The more businesses, governments, and communities that utilize this technology, the more we can expect to see:

- Fewer plastics dumped in landfills and oceans

- More jobs in recycling

- A cleaner marketplace for recyclables

The battle against plastic waste isn't simple, but with innovative solutions such as agglomerators, we're heading in the right direction.

Final Thought

The next time you encounter a plastic wrapper, consider it the building block of something fresh—a park bench, a pipe for water, or even another grocery bag. With agglomerators, the future has arrived—one pellet at a time.